You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

More flattened sphere tailsitters.

- Thread starter spank

- Start date

Spinward Flow

SOC-14 5K

Fun fact:

If you're dealing with a "flamey end down" style of tail sitter ... where do you put the cargo hold inside the form factor?

Do you put the cargo hold "in the middle" and need to have shore support in order to load/unload the cargo hold (because you're unlikely to be able to "drop a ramp" from that height to any external infrastructure that has commonality with other craft)?

If you use some sort of SpaceX HLS inspired swing out crane lift system ... you're going to bottleneck how much you can lift/lower into the cargo hold by the size of of the crane lift/cargo elevator capacity. You don't just have a volume limit but also a weight limit (especially if local gravity can vary because you're going to different planets) for the cargo lift/cargo elevator.

Ironically, these considerations are mostly "waived" if you're docking/berthing at high ports.

So the Configuration: 6 tailsitter is "less than optimal" for any kind of roll-on/roll-off cargo marshaling under local gravity on a planetary surface ... but works perfectly fine as a float-on/float-off cargo marshaling in zero-g at a high port ... which completely missed the point of being able to descend through atmosphere to a downport (where there's going to be local gravity).

I dunno ... it just feels like a solution that CREATES more problems than it solves.

If you're dealing with a "flamey end down" style of tail sitter ... where do you put the cargo hold inside the form factor?

Do you put the cargo hold "in the middle" and need to have shore support in order to load/unload the cargo hold (because you're unlikely to be able to "drop a ramp" from that height to any external infrastructure that has commonality with other craft)?

If you use some sort of SpaceX HLS inspired swing out crane lift system ... you're going to bottleneck how much you can lift/lower into the cargo hold by the size of of the crane lift/cargo elevator capacity. You don't just have a volume limit but also a weight limit (especially if local gravity can vary because you're going to different planets) for the cargo lift/cargo elevator.

Ironically, these considerations are mostly "waived" if you're docking/berthing at high ports.

So the Configuration: 6 tailsitter is "less than optimal" for any kind of roll-on/roll-off cargo marshaling under local gravity on a planetary surface ... but works perfectly fine as a float-on/float-off cargo marshaling in zero-g at a high port ... which completely missed the point of being able to descend through atmosphere to a downport (where there's going to be local gravity).

I dunno ... it just feels like a solution that CREATES more problems than it solves.

Silverhawk

SOC-12

I think for me as a cargo vessel these are more likely to fit the bulk/granular commodities (pulverized ores, grains) where you can load via a tube/chute into the hold and have a discharge outlet at the other end. It is gravity fed in both instances which is fine.

Using cargo modules would as @Spinward Flow has pointed out wold require more infrastructure or take up valuable space to bring along and have available anywhere.

Still, they do have certain style to them.

Using cargo modules would as @Spinward Flow has pointed out wold require more infrastructure or take up valuable space to bring along and have available anywhere.

Still, they do have certain style to them.

kilemall

SOC-14 5K

I posit that it’s necessary due to delayed floor plate/inertial damping artificial gravity tech. As it becomes available belly landers become more the frontier downport norm.Fun fact:

If you're dealing with a "flamey end down" style of tail sitter ... where do you put the cargo hold inside the form factor?

Do you put the cargo hold "in the middle" and need to have shore support in order to load/unload the cargo hold (because you're unlikely to be able to "drop a ramp" from that height to any external infrastructure that has commonality with other craft)?

If you use some sort of SpaceX HLS inspired swing out crane lift system ... you're going to bottleneck how much you can lift/lower into the cargo hold by the size of of the crane lift/cargo elevator capacity. You don't just have a volume limit but also a weight limit (especially if local gravity can vary because you're going to different planets) for the cargo lift/cargo elevator.

Ironically, these considerations are mostly "waived" if you're docking/berthing at high ports.

So the Configuration: 6 tailsitter is "less than optimal" for any kind of roll-on/roll-off cargo marshaling under local gravity on a planetary surface ... but works perfectly fine as a float-on/float-off cargo marshaling in zero-g at a high port ... which completely missed the point of being able to descend through atmosphere to a downport (where there's going to be local gravity).

I dunno ... it just feels like a solution that CREATES more problems than it solves.

In the meantime, swing out cranes or grav raft platforms would be the norm for no gantry rough field cargo.

Spinward Flow

SOC-14 5K

That is my supposition too.In the meantime, swing out cranes or grav raft platforms would be the norm for no gantry rough field cargo.

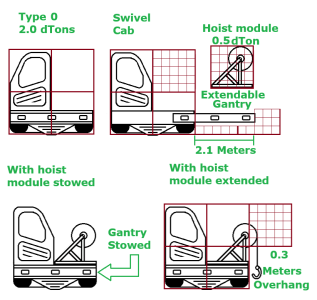

It would mean that for "austere locations" you're basically going to want/need to have your own air/raft for use as a cargo marshaling service assistant, giving you 3D "access" that would otherwise be problematic to move around. However, use of an air/raft for this purpose would "limit" any cargo marshaling to granularity bottleneck of 4 tons (maximum) per "lot" of cargo (partial or otherwise) that could be moved by air/raft. This would be fine for smaller breakbulk cargoes, but potentially problematic when trying to mobilize "larger" cargoes (say, 5+ tons, can't be subdivided further).

Hardly something that Traveller (as a rules set) ever spent much ink on, but once you start moving in the direction of Life Simulator ROLEplay ... it starts becoming a potential thorn in the side that would be best avoided (if you've got the option).

For specialized cargo handling, I agree that such arrangements can work out just fine ... but you quickly run into problems when wanting to have a more generalized type of cargo handling capability.I think for me as a cargo vessel these are more likely to fit the bulk/granular commodities (pulverized ores, grains) where you can load via a tube/chute into the hold and have a discharge outlet at the other end. It is gravity fed in both instances which is fine.

Most ACS (that we, as Players and Referees care about) are going to be oriented more for generic/generalist cargo handling work, so that your starship can "transport almost anything" from any and all clients wanting to buy freight tickets from you. The ability to "go anywhere" combined with the capability to "haul anything" (that fits in the cargo hold) is a necessary type of flexibility when looking at things from the free merchant tramp operator perspective on things.

@Spinward Flow

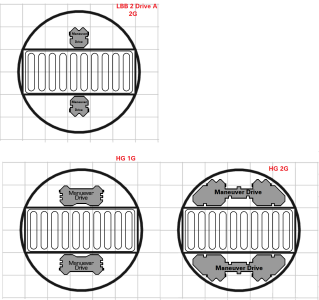

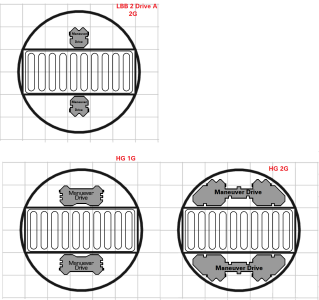

I don't think it's really that big of an issue, the "flamey end" equipment is relatively small. 1 dTon for a 2G drive in LBB 2, 2 Tons for a 1 G drive in HG or 5 Tons for a 2G drive in HG.

In the 100 dTon design that leaves plenty of room for a standard 5 Dton cargo module. I think you could also designate this space as a cargo lift and build other cargo deck above this. Presumably you would park your air/raft or grav fork lift on the bottom level, drive it off then unload cargo.

On Larger ships, with larger drives you could either make the drives multi-level or add external landing fins à la the Broadsword. In this case the two of the fins would serve as cargo ramps and two as engine areas. Assuming you use the whole middle section for drive-on/drive off cargo that leaves 43.4 dTons using only the cylindrical deck plan or 55.7 using the full section of the sphere. A Broadsword style trader would need on 40 dTons for a 2G drive under HG or 15 dTons for a 2G LBB2 drive. Add another 25 dTons for a rating 2 Power plant and you still have 15.7 Tons left for fuel. Overall on a LBB2 800 dTon ship rated for 2G w your bottom deck would have 32 drivethru cargo space, 40 Tons Drive space for Power Plant and Maneuver Drive, and 15.7 Tons fuel with 3.4 Tons in the cylindrical floorspace.

I don't think it's really that big of an issue, the "flamey end" equipment is relatively small. 1 dTon for a 2G drive in LBB 2, 2 Tons for a 1 G drive in HG or 5 Tons for a 2G drive in HG.

In the 100 dTon design that leaves plenty of room for a standard 5 Dton cargo module. I think you could also designate this space as a cargo lift and build other cargo deck above this. Presumably you would park your air/raft or grav fork lift on the bottom level, drive it off then unload cargo.

On Larger ships, with larger drives you could either make the drives multi-level or add external landing fins à la the Broadsword. In this case the two of the fins would serve as cargo ramps and two as engine areas. Assuming you use the whole middle section for drive-on/drive off cargo that leaves 43.4 dTons using only the cylindrical deck plan or 55.7 using the full section of the sphere. A Broadsword style trader would need on 40 dTons for a 2G drive under HG or 15 dTons for a 2G LBB2 drive. Add another 25 dTons for a rating 2 Power plant and you still have 15.7 Tons left for fuel. Overall on a LBB2 800 dTon ship rated for 2G w your bottom deck would have 32 drivethru cargo space, 40 Tons Drive space for Power Plant and Maneuver Drive, and 15.7 Tons fuel with 3.4 Tons in the cylindrical floorspace.

Attachments

kilemall

SOC-14 5K

Didn’t have the air raft in mind, more like say a 10 dton flat raft so you pile on 1dton cargo lots onto it for which deck you are storing it on, then fly right out, drop off the first batch and go back up to get the next load. Sort of an elevator lift with controls and not much else.

I thought about this a while ago, and made a big thread with cargo handling equipment.Didn’t have the air raft in mind, more like say a 10 dton flat raft so you pile on 1dton cargo lots onto it for which deck you are storing it on, then fly right out, drop off the first batch and go back up to get the next load. Sort of an elevator lift with controls and not much else.

Here's something I have been working on for a while, a standard method of shipping freight. While working on an adventure idea I codified the concept a bit more.

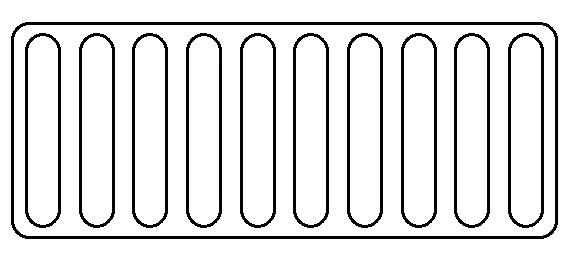

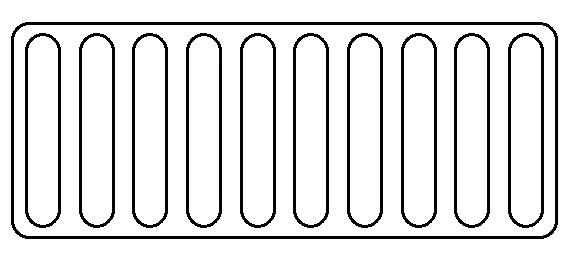

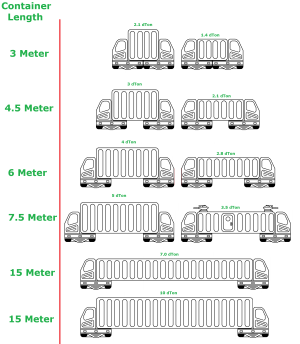

First up the standard 5 dTon shipping container: 2.9 x 2.9 x 7.4 meters. It's the standard cargo handling device across the Imperium.

Next the Air/truck, unloaded it takes up about 6 dTons, and costs 1.8 MCr, and can carry 3 passengers. It is specially designed to haul Imperial standard 5 dTon shipping containers. It can carry 3.3 Dtons of cargo within it's footprint stacked, on pallets or in a reduced height version...

First up the standard 5 dTon shipping container: 2.9 x 2.9 x 7.4 meters. It's the standard cargo handling device across the Imperium.

Next the Air/truck, unloaded it takes up about 6 dTons, and costs 1.8 MCr, and can carry 3 passengers. It is specially designed to haul Imperial standard 5 dTon shipping containers. It can carry 3.3 Dtons of cargo within it's footprint stacked, on pallets or in a reduced height version...

- spank

- Replies: 45

- Forum: Ship's Locker

After I got done I realized I'd made a mistake. I let modern paradigms taint the design. Ideally the cargo movers would slot into the end of the cargo module, rather than under it. That would make loading/unloading much easier. Slot into a module and pull it out rather than lift the module up and place it on the mover. then slot a second mover in the back end of the module slaved to the first. Drive it to a staging area and return to the ship for another cargo module. Large ports will have a number of Grav-movers to facilitate offload, and ships will carry a pair to use at remote backwater facilities.

Someday I'll draw up some of the end attach cargo movers.

Last edited:

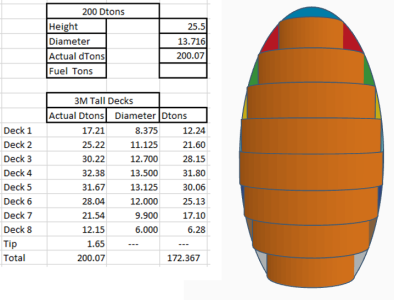

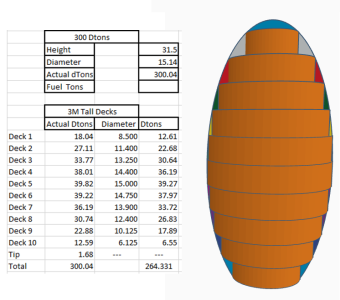

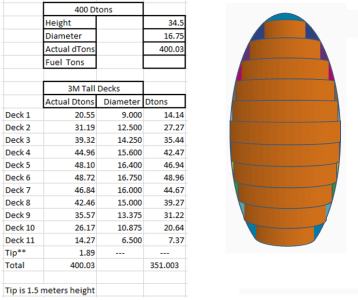

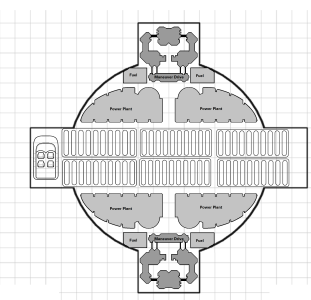

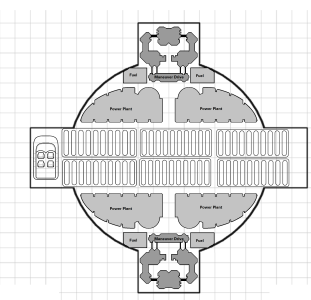

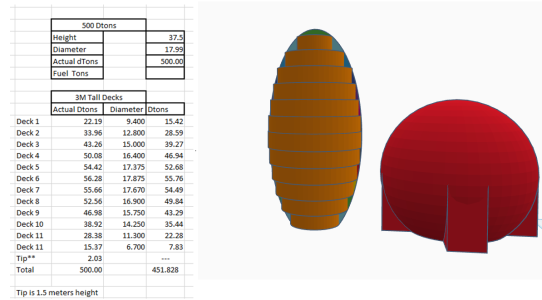

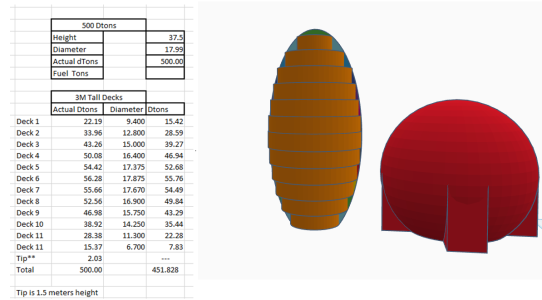

Next up: the 500 dTon Hull

Next to it is a 800 ton Broadsword-esque hull. 18.51 meters Diameter, 16 Meters Height. I might change the height so it's 1.5 meters taller so the top level is better shaped/not as wasteful of space.

Also of note, the fuel fraction/ unused mass is improving, it was about 15% on the 100 dTon design, and is under 10% on this design.

Next to it is a 800 ton Broadsword-esque hull. 18.51 meters Diameter, 16 Meters Height. I might change the height so it's 1.5 meters taller so the top level is better shaped/not as wasteful of space.

Also of note, the fuel fraction/ unused mass is improving, it was about 15% on the 100 dTon design, and is under 10% on this design.

Last edited:

Spinward Flow

SOC-14 5K

That's just how the geometry adds up when you need to "square the circle" in order to make things fit. The more discrete vertices available (in this case, decks) the less wasted space you have when transitioning from one form factor (flattened sphereoid) to another (stacked "slabs" of cylinder).Also of note, the fuel fraction/ unused mass is improving, it was about 15% on the 100 dTon design, and is under 10% on this design.

AnotherDilbert

SOC-14 5K

Next up: the 500 dTon Hull

View attachment 7287

The disadvantage with the small tail-sitter with many small decks is that you waste a lot of space on stairs/elevators and corridors. A big central 3 × 3 m elevator would take 24 Dt, almost 5% of the ship.

Small circular deck are difficult to layout efficiently.

Badenov

SOC-13

Depending on your degree of fine control of ship gravity (assuming you're not just relying on 1G thrust to simulate gravity, which admittedly is the big arguement for tailsitters), all you need is a single tube where gravity is completely absent. Alternately, a ladder and give everyone a bit of workout.The disadvantage with the small tail-sitter with many small decks is that you waste a lot of space on stairs/elevators and corridors. A big central 3 × 3 m elevator would take 24 Dt, almost 5% of the ship.

Small circular deck are difficult to layout efficiently.

Corridors ought to be factored in to other required spaces, for instance in MgT1 the space for passageways is specifically addressed. 'While the tonnage allocated to staterooms includes air refreshers, passageways, mess halls, crew lounges and other living space, it is often cramped and uncomfortable.' (MgT1 p110 in the paragraph on luxuries). I'm not sure if CT makes the same assumption, but I expect so. And whatever means you give for travel between decks, that ought to come out of your corridor tonnage also. It does mean the larger your elevator, the smaller your staterooms.

If you're trying to install rectilinear components, yes.The disadvantage with the small tail-sitter with many small decks is that you waste a lot of space on stairs/elevators and corridors. A big central 3 × 3 m elevator would take 24 Dt, almost 5% of the ship.

Small circular deck are difficult to layout efficiently.

As a counter-example, I present the 1.5m-square elevator shaft in my S-as-Tailsitter design. It transits the fuel tank at 1/2Td per 3m, where a standard 1.5m-wide corridor (lengthwise) would take 1Td for each 3m of corridor. The horizontal equivalent is a 1.5m*1.5m access tube, perhaps with a trolley to lay upon... (or in low/0 G).

It does suggest, however, that I incorporate into such designs, some normally-locked and usually-ignored 3m*3m inter-deck hatches for moving large objects around. (For bulk supplies, large components, furniture, etc.)

AnotherDilbert

SOC-14 5K

A ladder moves you, but no equipment, as GravMoped alludes to.Depending on your degree of fine control of ship gravity (assuming you're not just relying on 1G thrust to simulate gravity, which admittedly is the big arguement for tailsitters), all you need is a single tube where gravity is completely absent. Alternately, a ladder and give everyone a bit of workout.

Elevator or grav shaft, it's the same tonnage.

It's the same in most editions, and certainly CT.Corridors ought to be factored in to other required spaces, for instance in MgT1 the space for passageways is specifically addressed.

With small circular decks you end up with very small staterooms with curved walls, rather impractical...

AnotherDilbert

SOC-14 5K

Sure, good enough for a very small crew. When we are approaching a Broadsword, we need more or larger elevators, or probably both...As a counter-example, I present the 1.5m-square elevator shaft in my S-as-Tailsitter design. It transits the fuel tank at 1/2Td per 3m, where a standard 1.5m-wide corridor (lengthwise) would take 1Td for each 3m of corridor. The horizontal equivalent is a 1.5m*1.5m access tube, perhaps with a trolley to lay upon... (or in low/0 G).

Quite, that would work, just a bit fiddly to have open space in the same space on all 12 decks, in addition to the personnel elevators.It does suggest, however, that I incorporate into such designs, some normally-locked and usually-ignored 3m*3m inter-deck hatches for moving large objects around. (For bulk supplies, large components, furniture, etc.)

Spinward Flow

SOC-14 5K

That's the bottleneck in marshaling that I was talking about earlier.It does suggest, however, that I incorporate into such designs, some normally-locked and usually-ignored 3m*3m inter-deck hatches for moving large objects around. (For bulk supplies, large components, furniture, etc.)

Yes, it can be done ... but it LIMITS what you can DO.

Setting limits on the "granularity of how much can be moved" has practical implications when you move beyond the spreadsheet (which doesn't really "care" about these issues) and start needing to deal with the problems of needing to move through dimensional constraints (such as access sizes and/or lifting capacity for 3D movement). Needing to "SORT the Fine Art of Packing" (so everything can be loaded and unloaded) is where Steward skill (of all things) comes into play for the work of a Supercargo as part of the Service Crew.

Badenov

SOC-13

Yes, but moving that degree of heavy equipment between decks while underway ought to be a wildly infrequent task. If it's cargo, each deck should have its own cargo door because it's wildly easier to put in a cargo door than an elevator, and you get the elevator's footprint at each level back as storage space. On a many-level ship, that adds up. In the Navy, we could remove the inclined ladder (stairs, but held in place by pins), rig a chainhoist, and lift out heavy bits. I saw this done 1 time in 4 years, and that was to take it off the ship.A ladder moves you, but no equipment, as GravMoped alludes to.

Elevator or grav shaft, it's the same tonnage.

This is what I had assumed, but couldn't say for sure.It's the same in most editions, and certainly CT.

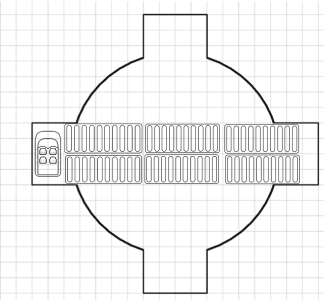

Impractical, perhaps, but far from impossible. Consider the attached, very notional, circular deckplan. several rooms roughly rectangular, with a bed along one flat wall, a fold-down desk opposite, and a storage area/armoire/cabinet/closet along the curved wall, where the curve is much less obvious because it's behind all the things in the storage area. The center circular area is a common area and might have showers/galley spaces, or what have you.With small circular decks you end up with very small staterooms with curved walls, rather impractical...

Attachments

Spinward Flow

SOC-14 5K

That works just fine for larger radii in dimensions, because the resultant "slices" have more of a trapezoidal shape to them that almost but not quite rectangular. You're also correct that the "central area" is obviously where "shared/communal spaces" ought to be located.Impractical, perhaps, but far from impossible. Consider the attached, very notional, circular deckplan. several rooms roughly rectangular, with a bed along one flat wall, a fold-down desk opposite, and a storage area/armoire/cabinet/closet along the curved wall, where the curve is much less obvious because it's behind all the things in the storage area. The center circular area is a common area and might have showers/galley spaces, or what have you.

However, when the radius gets smaller, the "trapezoidal distortion" away from a rectangular dimension sizing increases ... until reaching a breaking point where an unacceptable fraction of the interior area becomes unusable or otherwise "wasted" space. So definitely a condition of ... we make it up in volume ... that favors the Big over the Small (or words to that effect).

Similar threads

- Replies

- 111

- Views

- 10K