This is where you're going to start running into issues of baseline assumptions ... and where those assumptions "come from" in order to generate constraints.

For example.

Why are multi-modal ISO shipping containers

that size and shape? Why does the TEU have those dimensions?

Simple answer: To "fit" within the constraints of dimensions allowed for road and rail transport under 1G environmental conditions.

Road (and rail) infrastructure has limits on the

width of stuff that can be transported safely (without contact with the surroundings).

Likewise, road (and rail) infrastructure passes under bridges, which have height limits, and you don't want to be "can opener on contact" with bridge works overhead while transporting stuff.

The choke point here is that the road and rail infrastructure all existed prior to the development of the ISO standard multi-modal shipping container ... so the "standard box" had to fit within the constraints already in place for those modes of transportation.

Gravitics CHANGES ALL OF THAT.

With gravitics, you aren't "limited" to transport routes along a world surface. You can literally "move stuff through the sky" (with or without atmosphere!) and have "plenty of room" to work with. You don't HAVE the same dimensional constraints as surface transport (road, rail, water, etc.) need to "fit" within.

Low bridge?

No problem. Just use your gravitics to fly over it.

Narrow tunnel?

No problem. Just use your gravitics to fly over the terrain feature that required making a tunnel.

Can't do 2 lane Oversized Load transport on roads?

No problem. Just use your gravitics to fly over the road so you don't get snarled and block the road traffic.

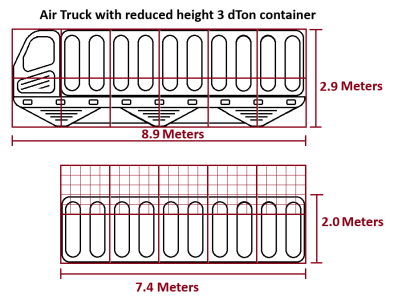

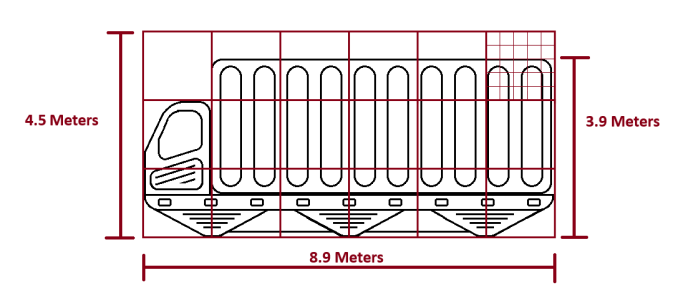

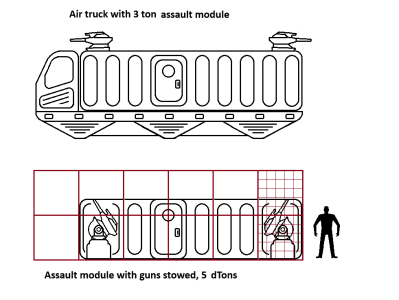

With gravitics, you need to stop thinking in terms of "trucking" as your form factor to start with and start thinking in terms of skycrane/helicopter type slung loads.

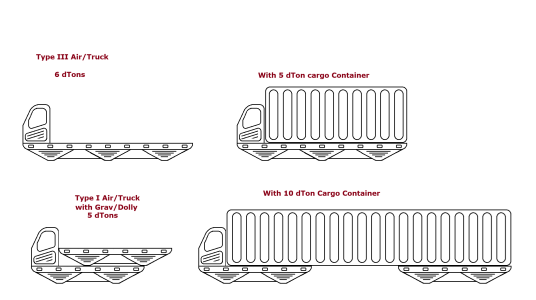

For example, the flatbed truck form factor requires loading stuff ON TOP of the flatbed.

But if you invert that (into a "flat roof" form factor?) you have something that can hover DOWN on top(!) of a standard container, "grab on"/secure the load from the dorsal ... and then just lift upwards into the sky and start laterally moving where the container needs to go. You shift from a notion of putting things ON TOP of other things in order to move them around, to being able to SLING UNDER other things in order to move them around ... because with gravitics, vertical height is less of a constraint.

The surface infrastructure necessary for mobility with gravitics is more of a "helipad" type arrangement, and in a lot of cases you can "pick up and put down" almost anywhere, sky crane style.

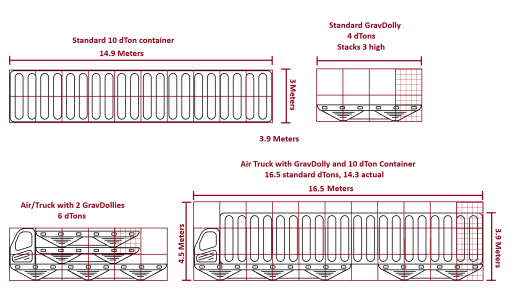

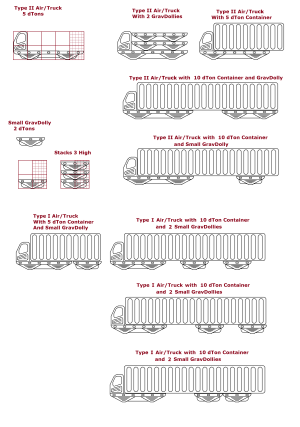

In practical terms, this means that the "ideal shape" for a gravitics lifted modular container stops being a "long thin box" modeled after the TEU and other multi-modal ISO shipping containers meant for surface transport networks exclusively.

Instead, what you start looking for are "prismatic shapes" (so sticking with rectangular sides for stacking/packing efficiencies) that minimize the surface area of the ventral/dorsal plate sections ... so something that is more of a square-ish type of form factor in 2D. You then want to make the 3D height something that is "convenient" for the types of (interstellar) transport you're going to be wanting to do.

This is where the "single deck" 10 ton Box and the "double deck" 20 ton Box form factors start coming into play, when you've got gravitics available to marshal and move them around.

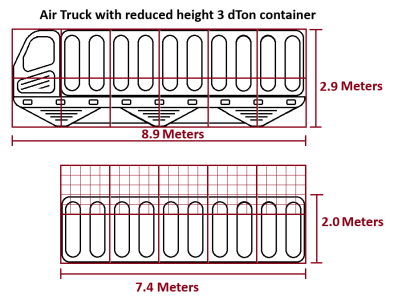

Working backwards from a 1 ton = 14m

3 baseline, and assuming a "single deck" height of 3m (so as to be able to load into starship holds):

- 10 * 14 = 140m3 / 3 = 46.66666667m2

- √46.66666667 = 6.83130051m

For reasons of practicality (not to mention, deck plan sanity!), you could use a 6.75m x 6.75m x 3m = 136.6875m

3 form factor, which on deck plans would be 4.5x4.5 deck squares in size, for the containers.

Now, for a surface transport (road, rail, water, etc.) ... a 2D footprint of 6.75m x 6.75m seems LUDICROUS.

That's 22'2" wide/long (for those still using archaic measurement systems) ... and for anything dealing with road/rail network transport, you'll require MORE space than that just for clearance around such an Oversized Load (that takes up 2 lanes of standard width/gauge traffic).

But for a mobility and delivery systems that rely on gravitics ... it makes perfect sense.

You get the "greatest volume" in the smallest 2D footprint within the limitation of a 3m height form factor that can be loaded into starship cargo holds for interstellar transport.

There's "room" to play around with the exact specifications, such as saying that the containers need to be 2.8m high because the starship hull ventral bulkhead to dorsal bulkhead (middle of to middle of) distance needs to be set at a STANDARD of 3m ... and in order for the standardized shipping containers to "fit" within that constraint, the containers need to be "shorter" than 3m in order to obtain clearance for loading/unloading.

In that case ... you could do 7m x 7m x 2.8m = 137.2m

3 as your 10 ton form factor (4.67 x 4.67 deck squares) baseline.

But then, once again, you're going to run into problems with trying to "play TETRIS" and fit some vehicle types into that form factor.

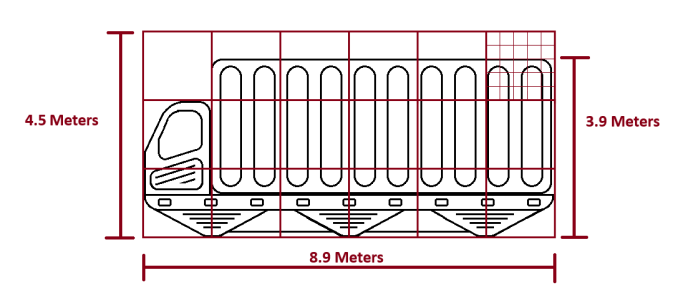

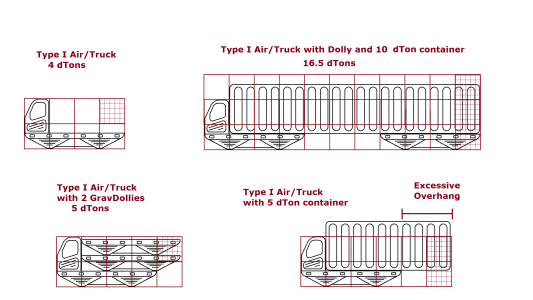

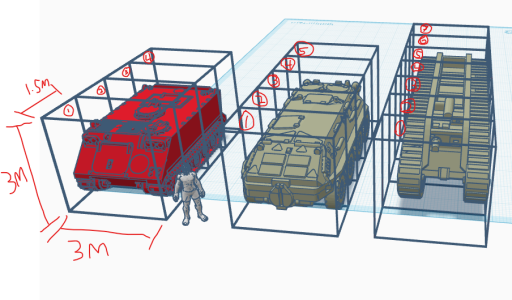

For example, the Geomorphs tile set for deck plans has GCarriers (8 tons) and ATVs (10 tons) in the inventory of shapes to be used for deck plans ... and they'll usually be more like 9m long and 4.5m wide.

Oops.

In fact, using the high resolution Geomorphs tile set ... a 10 ton Wheeled ATV requires 1825x806 pixels just for the ATV itself (never mind "clearance" space around it for "access" when berthed). At 300 pixels per deck square scaling, that means 9.125m x 4.03m (6.0833x2.6867 deck squares) MINIMUM in order to "fit" the 2D footprint of an ATV when it comes to deck plans.

So in order to "fit" the form factor of a 10 ton ATV, you need to abandon the notion of using a "square" form factor shape and return to something that is more rectangular/boxy.

If you shift over into an assumption of 2L/1W for the rectangle shape to fit an

ATV (and to make Jenga stacking easier) and continue the assumption of a 2.8m "single deck" height for a modular container that needs to "fit" within the 3m clearance of starship single decks for loading into cargo holds ... you find,

THIS:

- 10m x 5m x 2.8m = 140m3 = 10 tons

- 6.667 x 3.333 deck squares

Therefore ... by process of elimination and due to starting from first principles ... I submit to you that the "standard" 10 ton multi-modal interstellar shipping container intended for use in a gravitics technology logistics system would be ...

10m x 5m x 2.8m = 10 displacement tons ... in size.

You could then "stack" that form factor in arrays to achieve larger "blocks" of volume ... such as double wide (10m x 10m x 2.8m = 20 tons) ... before moving into "double deck heights" for 20 tons/40 tons segmentation of enclosed volume spaces.

But the 10m x 5m x 2.8m "box" form factor is what you ought to be using for your "grav truck" lift notions ... whether that be a cab+flatbed dorsal loader type, or a cab+spine ventral lifter type of logistics vehicle.

Hope that helps.

And yes, I'm going to be using this analysis of the ATV "box" form factor requirement when I (finally!) get back to working on my own modularized shipping container "box" merchant starship deck plans.